5 Tips To Help You Safely Use A Table Saw

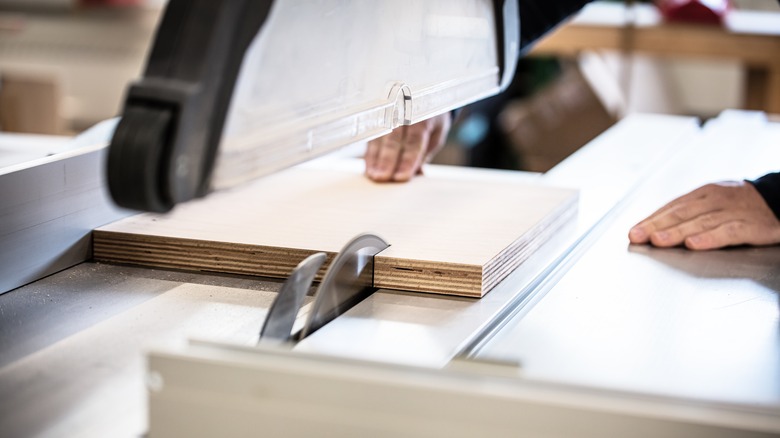

The table saw is one of the most used woodworking tools in the U.S., popular among professionals and DIY enthusiasts. In fact, statistics show that nearly 10 million table saw machines are used in home workshops across the U.S. The table saw is central to any woodworking shop; it features a circular blade that is powered by a motor, delivering accurate and precise cuts. While this instrument is valuable to woodworkers, it is also the most dangerous, causing severe injuries to many operators yearly.

According to Chaffin Luhana LLP, table saw injuries amount to about 67,000 cases, causing an estimated $2.1 billion in medical fees annually. With that said, does it mean that you cannot use this tool whatsoever? Absolutely not! It is worth mentioning that safety begins with you, and by taking some simple precautionary measures, you should be able to keep yourself out of harm's way. Most of the table saw-related injuries are caused by negligence by the user. Here are a few tips and tricks that should help you avoid injuries when using a table saw.

1. Use a push stick

No doubt using a table saw always comes with an element of danger; think about it, you are pushing a piece of wood in the direction of a spinning blade. You need protection to keep your fingers safe; that is where a push stick comes in. A standard table saw comes with a single push stick which is enough for the most part. But two dangers are associated with a table saw: injury caused by the blade and harm due to kickback action. Woodworking for Mere Mortals details that a kickback occurs when the blade grabs the piece of material and throws it back in your direction, causing fatal injuries.

Kickbacks might not cause injuries every time; in some scenarios, they may result in irregularly cut wood, leaving you with disappointing results. One way of keeping yourself safe from kickbacks is using a push stick. A push stick keeps your hands far from the blade, and in the event of a kickback, your fingers won't get drawn to the sharp edge. Moreover, a push stick gives you better control of the workpiece you are cutting, reducing the risk of kickbacks and allowing you to make precise cuts.

2. Do not use gloves

Outside the workshop, gloves are good for all the right reasons; they keep hands warm during winter and germs away. However, when it comes to working with table saws, there is no room for gloves whatsoever. You can wear gloves when doing other activities in the workshop, for instance, handling wood in the initial stages. However, wearing gloves is likely to cause more harm than good when using a table saw. This is because woodwork operation with the table saw heavily depends on the craftsman's sense of touch.

Wearing gloves means you cannot feel the board's movement; therefore, you may have a delayed response to critical situations. Also another danger of using gloves when handling a table saw is that the fabric can get caught on the blades causing even more damage. Essentially, it is proper to avoid wearing gloves when using any tool with a rotating blade, via the Ohio State University Extension. Remember, cut-proof gloves will not stop the table saw from doing what it is meant to do, which is to cut!

3. Use featherboards

Although not emphasized enough, a featherboard is an invaluable piece of equipment that every woodworker must have. According to Rockler, the featherboard serves two main purposes, holding the workpiece firmly against the fence and providing extra safety to the operator. When working with a table saw, there is always a risk of kickback causing injuries to the operator. When a featherboard is correctly placed on the table, it applies constant pressure to the workpiece allowing you to make precise and accurate cuts while at the same time preventing the possibility of a kickback.

Because of the featherboard fingers' orientation, it should be easier to push the workpiece forward than it is to drive back. This mechanism is responsible for keeping the workpiece firmly on the track. While recent table saws come with a standard featherboard, you can make one right in your workshop. DIY featherboards are more comfortable and user-friendly, and you won't incur any costs.

4. Adopt proper positioning or stance

Part of the safety measures when using the table saw, and any other equipment for that matter, is stability during operation. The proper stance that gives you the most solidity is standing with your feet a few feet apart. Avoid standing with your feet together or leaning on one foot while operating the table saw. When it comes to positioning, avoid standing right behind the table; instead, work on the piece from the side.

This will ensure you don't get hit by the workpiece if a kickback happens during operation. ShakeDeal advises that the correct positioning while operating the table saw is to the left of the blade. This position is quite strategic because it is comfortable for the operation, putting the blade between the fence and the operator. Lastly, if the positioning of your arm doesn't feel comfortable or is unnatural, don't force it. Step back, rethink, and adjust your stance. It is better to be safe than sorry.

5. Use the right blade

As cliché as it may sound, a sharp blade is always a safer blade; therefore, before beginning any cut, be sure that the edge you are using is honed and ready for the task. A blunt blade is also very slow and will consume much energy to cut the same workpiece. For an untrained eye, it can be difficult to tell if your blade is dull. However, ToolBoxToday mentions that if you notice burn marks that did not previously exist or you are finding it hard following cut lines, chances are you are using a dull blade. Something else to consider is to use the right blade for the right cut.

Some accidents occur because the woodworker deliberately decides to switch blades and use them on the wrong workpiece. A good example is a scenario where one chooses to use a blade for ripping to cross-cut. This is quite dangerous because the blade will likely break and cause the projectiles to fly in different directions, causing severe injury to whoever is in the way.