What Is A PEX Pipe And Why Is It Important?

For decades, copper piping was a common choice for home plumbing. It does it all — it's fully recyclable, bacteria and corrosion resistant, and it works well with chlorine and fluorine, meaning that the quality of your water will stay high over time. But with those perks comes a steep price due to the cost of the material alone, let alone its effect on your water bill — since the metal is so rigid, water can't speed through pipes, leading to a higher monthly payment in the long run (via Meadowlark Builders).

So forget the galvanized and copper pipes — there's actually an entirely different option, known as PEX piping. Despite being first introduced in Europe in the 1970s, it didn't make waves in the U.S. residential plumbing scene until the 1980s, reports Plumbing & Mechanical Magazine. Nowadays, this plastic alternative can be found in the plumbing system of budget-friendly new builds and under heated floors, but what exactly is it? We're here to break down what a PEX pipe is, and why you need to integrate them into your home sooner rather than later!

What is a PEX Pipe?

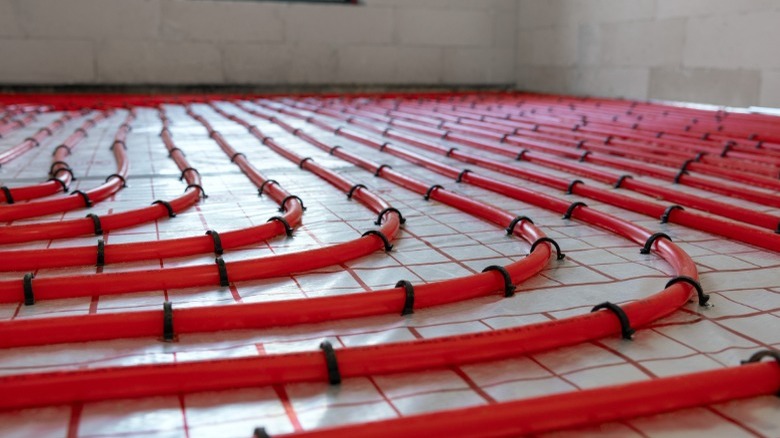

Also referred to as cross-linked polyethylene, a PEX pipe is a synthetic, thin piece of plastic piping that can bend and mold however you need for it to fit in a space. It first gained popularity as a simple way to install heated floors, since it has great thermal properties at a fraction of the cost compared to traditional options, but is now a standard cost-friendly plumbing option in new construction, says Benjamin Franklin Plumbing. If you buy a property in a new community full of fresh-on-the-lot start homes, chances are, you'd find these red, white, and blue plastic pipes in your walls.

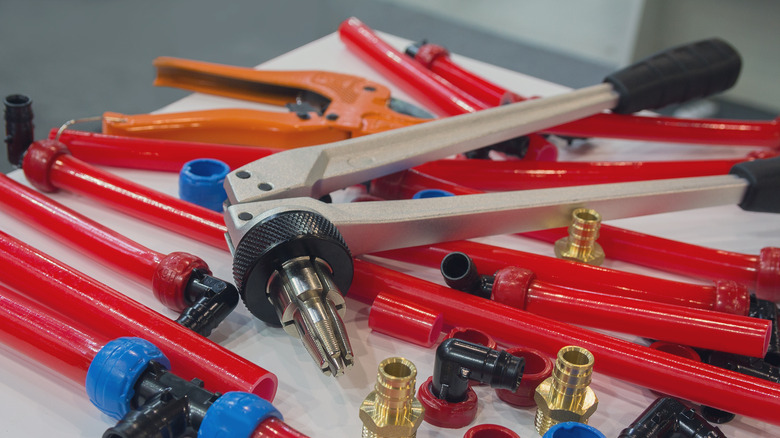

There are a few different types of PEX piping known as A, B, and C, but all are created by cross-linking polymer molecules in polyethylene, which gives it flexibility. Many DIYers are a fan of the product, since it's malleable and easy to work with no matter your skill level, especially compared to copper piping (so long as you do your research). Meadowlark Builders notes that PEX pipes are also 100% resistant to acids, so if you have particularly finicky water with a pH below 6.5, it's a no-brainer pick over copper, which will corrode in no time.

Pros of PEX Pipes

The price tag is the most obvious advantage of installing or switching to PEX pipes. Berkeley Plumbing and Heating Co. claims that they're only 25% of the price of copper, which can be a significant saving. PEX pipes also need fewer connections, and you don't need soldering torches or glue to install them, so you can use fewer tools and materials. This is all because PEX pipes are made from synthetic materials, making them more flexible than other pipes. PPFA (The Plastic Pipe and Fittings Association) adds that PEX pipes bend around corners, eliminating the need for joints and other fittings. That also cuts down on labor, and plumbers charge by the hour. There's no doubt that PEX pipes are easier to install, whether for new plumbing or retrofitting established systems.

Another advantage of that flexibility is its ability to expand when the water inside it freezes. And just as importantly, PEX returns to its original shape after temperatures decrease. It is less likely to crack or burst since it resists freezing. These pipes also keep water hot and improve water pressure. You can expect PEX pipes to last for approximately 50 years.

Cons of PEX Pipes

PEX pipes also have some caveats. After installation, they require a week-long flushing regimen to eliminate potential chemicals that might be in the water. They are not UV-resistant and will break down quickly when exposed to the sun. And since they're made from a permeable material, anything from the environment can seep into your water supply without the proper precautions.

Another major con is that PEX pipes cannot be joined directly to water heaters or close to any recessed lighting because they're quick to fail when overheated, warns Benjamin Franklin Plumbing. Be sure to map out any repiping with a professional to avoid damage to the system down the line.

PEX pipes can also fail for a few different reasons. Plastic Expert Group points out that these pipes are prone to stress when installed incorrectly. Exceeding the maximum bend radius or leaving kinks in these pipes could cause problems. Expansion fittings must be appropriately installed since the tubing shrinks onto them. Other issues can arise when PEX pipes are defective; signs of this might include brittleness and degradation.

What the different colors of PEX pipes mean

PEX pipes have different thicknesses and temperature range ratings, and come in different colors, including blue and red. But Rowin Plumbing explains that even though PEX pipes come in various lengths and diameters, the colors don't reflect that. They signify something else: whether the pipe is for hot or cold water. When a PEX pipe is blue, it carries cold water; red pipes are for hot. That makes it easy to remember, but white and gray PEX pipes are made for both.

Various manufacturers use blue, red, and white pipes in this way. SharkBite also sells orange PEX pipes specially designed for hydronic heating applications; they work as oxygen barrier pipes. However, red, blue, white, and gray pipes can theoretically be used interchangeably; they aren't made differently to withstand different temperatures. Instead, the colors help plumbers distinguish between hot and cold water.

Installation cost

So if the pros outweigh the cons and you're in the market to repipe your home, the next question is obvious: How much will it hurt my wallet?

According to The Repipe Company, the average cost to refinish a standard-sized home with PEX pipes is between $4,200 and $6,000. Of course, that number varies based on several different factors, like how large your home is. If you have multiple stories, expect the cost of the job to rise, since some demolition will be required to squeeze in new vertical pipes. The same applies for if your home has lots of little nooks and crannies — plumbers will charge more for labor when they have to work in hard-to-reach areas, like closets and cupboards.

The cost of the job also rises with the amount of fixtures in your home, since it'll require more materials and connections throughout. Fortunately, PEX pipe rings it at about $.50 to $2 per square foot. Copper starts at $2/square foot, and can even reach $4/square foot, says The Repipe Company. That's more than double for the same level of quality material!

Generally speaking, PEX piping is cost-effective — there's no doubt. But a major plumbing overhaul is still an investment, so it's best to do research for prices in your area and receive a quote from a professional to really make the final call on copper versus PEX.

PEX pipes vs CPVC

CPVC (chlorinated polyvinyl chloride) pipes are rigid rather than flexible, according to PPFA. It is used in residential construction, and is resistant to chlorine damage, corrosion, and high temperatures. Plastics Pipe Institute explains that CPVC is basically a PVC pipe that's reinforced with chlorine during the manufacturing process. It comes in a wide variety of sizes and is universally compatible with different fittings. CPVC is also lightweight and durable, and no flames are needed for installation (it's also flame-resistant). And according to PlumbingSupply.com, CPVC is non-toxic, so you don't have to worry about chemicals leaching out. The pipes won't melt, and the water supply stays pure. CPVC pipe is also well-insulated and keeps water at the right temperatures.

When comparing PEX to CPVC, both pipes can handle temperatures up to 200 degrees, but only PEX can withstand below-freezing conditions. PEX pipes are also more flexible, less expensive, and easier to install because you don't need as many connections. But, since it cannot survive UV rays, it can't be installed outside. FlowGuard Gold claims that CPVC pipe will discolor after being exposed to UV rays, but will still be able to handle water pressure.

What are non-oxygen barrier, oxygen barrier, and aluminum barrier PEX pipes?

Many PEX pipes are made with barriers that serve as insulation. Non-barrier PEX is suitable for pipes that transport and hold drinking water. Oxygen gets through, which can be an issue if your pipes or system contains iron components. Oxygen-barrier PEX pipes have an added layer that keeps oxygen from getting in, but these pipes should not be used with drinking water sources. When oxygen in water gets into pipes, iron parts can corrode. So if your system has any iron in it, you need to install oxygen-barrier PEX pipes specifically.

Plastics Pipe Institute explains that aluminum barrier PEX pies have aluminum tube reinforcements inside them. Also called PEX-AL-PEX, the aluminum prevents oxygen from getting into the water. While oxygen barrier PEX pipes have an extra layer on the outside, aluminum barrier PEX pipes have an added layer between the inner and outer PEX layers. Non-oxygen barrier PEX pipes are used for potable hot and cold water plumbing lines, and for open-loop hydronic heating systems. Oxygen and aluminum barrier PEX pipes are for closed-loop hydronic systems, snow melting, and radiant floor heating.