The Truth About Reusing Wire Nuts For Electrical Work At Home

If there's one place to be overly cautious when doing household repairs, it's electrical work. Electrical issues cause roughly 51,000 household fires annually, according to the ESFI, resulting in hundreds of deaths and over $1 billion in property damage each year. Whether you're installing a ceiling fan or screwing in a light bulb, no step is too minor to carefully consider. Even something as simple as reusing a wire nut can be a consequential decision and one you're likely to encounter at some point in your DIY adventures. With that in mind, it's critical to understand whether you can reuse an old piece or if you're better off going to the store to buy a new pack of wire nuts to ensure the safest possible connections.

Generally, reusing wire nuts is a practical way to save time and money, but it doesn't come without significant considerations. Homeowners often have these spare pieces lying around the house, so if they're clean and undamaged, you may be able to reuse them. Importantly, the wire nut must be the proper size. You can't always use any random leftover wire nut. If it's too big or small for the gauge or number of wires, you risk a loose connection that could cause an electrical failure at best and a fire at worst. Manufacturers have color codes to help you find the right size wire nut for the wire gauge, so always compare the two to guarantee a proper fit.

Safety considerations for reusing wire nuts

Even if it's the right size, there could be other issues precluding the safe reuse of an old wire nut. Convenient as it may be, you don't want this small cap to be one of the unnecessary dangers lurking around the house, so take a few moments to assess its condition. Is there any dirt, liquid, or corrosion in the wire nut? While you can clean out moisture and debris, rust and damage to the springs should disqualify it from reuse. Getting a solid bite into the wire is critical for a safe connection, which isn't likely if there's any permanent damage to the threading.

Check for cracks around the casing as well. Over time, the wire nut may degrade or deform, affecting its ability to twist onto wires or hold securely. Signs of damage, particularly burn marks, mean you should skip it. While you check the plastic case, check for industry markings suggesting the item's quality. You'll know the wire nuts have met rigorous standards and are generally well-made if they bear UL and CSA certification marks and come from well-known brands. If you're uncertain about the quality, you may want to avoid reusing the wire nut and play it safe with a new one.

Creating a safe connection when reusing wire nuts

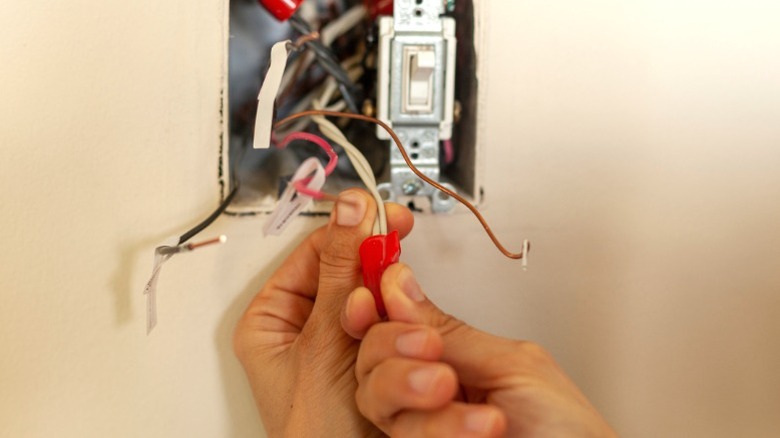

Reusing a wire nut for electrical work requires a similar process as a fresh wire nut, though you should take a few extra precautions as you install it. Strip the wires about ¾ of an inch, being careful to avoid dangerous mistakes when using wire strippers. Then, line the wires up so the ends are flush. At this point, you can check for manufacturer marks on the wire nut so you can look up specific instructions online, as some brands say you don't need to pre-twist wires before installing the connector. But pre-twisting wires is generally a safe practice, creating a solid grip between the two wires to prevent them from separating as you fit the wires into place. Using a pair of pliers, twist the ends a few times around each other. Then, cut off about ¼-inch of wire from the end of the twisted pairing.

Attach your wire nut to the end of the exposed wires, screwing it on in a clockwise rotation. You can then double-check if the wire nut will work for the application. Look for exposed copper wiring going past the end of the wire nut, which will require you to cut the wire shorter to make it all fit under the cap. If that looks fine, do a quick tug test to check that it's secure. Gently pull the wires to ensure they don't easily slip out. With a firm connection in a clean, undamaged wire nut, you can confidently reinstall the wiring.