10 Tips To Significantly Cut Costs When Building Your Own Cabinets

We may receive a commission on purchases made from links.

Building your own cabinets is well worth the time and effort if you're looking to save money and learn new skills. All the resources for crafting cabinets are available online and in brick-and-mortar stores, and anyone with enough drive and curiosity could complete this project. The main perk of building cabinets yourself is that you aren't paying for professional labor, which leaves a bigger budget for higher-quality materials and customization decisions. You have full control over the project, and if you learn a few industry secrets, you could cut even more costs.

There are tips and tricks to learn from all corners of social media and the internet, from professional cabinetry websites to small-time blogs and video content. Homeowners already save between $35 to $380 per linear foot of cabinetry when they don't hire professional laborers. You can supercharge these savings further if you know where to buy supplies, what materials and tools you really need, and how to optimize your kitchen design. Follow these cost-cutting strategies to save anywhere from a few hundred to thousands of dollars. Read on to learn more about how they work, why they work, and how much you can save by implementing these tips throughout the cabinet-making process.

Get multiple quotes if you need a professional for any part of the project

If it's your first time building cabinets, you may come across a part of the project that's beyond your capabilities. Rerouting plumbing or rewiring electricity necessitates professional skill and are two types of home renovations that may require permits before starting, which the right contractors can help you obtain, while also ensuring the installation is up to code. Additionally, work and life issues may arise, rendering you unable to finish your renovation job. In either case, don't rush to hire the earliest available contractor. Read online reviews, browse local businesses, and get free quotes from several companies before you commit.

Getting quotes from multiple people is important so you can figure out how to work with the right contractor to get what you want. It helps you determine a fair price, and it prevents unethical businesses from taking advantage of your naivety. All kinds of factors go into why contractors charge how much they do. A more experienced company with higher quality work standards might charge you slightly higher than an up-and-coming local business. Most contractors charge enough to make a 10% to 20% profit off the total project cost. Letting them charge more than that could cost you a few hundred or thousand dollars. Since you've probably done part or most of the cabinet work up until this point, take advantage of your newfound knowledge when signing a contract. You should have a pretty good idea of what they're investing in materials and fittings, and if the line items on their invoice seem inflated, you should get other opinions.

Ask carpentry professionals or search Google for cheaper plywood suppliers

Getting started is the hardest part of a woodworking project, especially if you have zero experience. The worst thing you can do is drive to the nearest hardware store and purchase the cheapest plywood in bulk. Retail shops are a third party, and they have to profit off the plywood they purchase. Prices aren't the best, and the selection is often limited. Contact professional carpenters and woodworkers in your area and inquire where they get their wood. If you aren't comfortable asking a real person, you can also search Google for local plywood suppliers.

Plywood suppliers don't usually advertise themselves to the public because their primary business is retailers and woodworking professionals. Scour their social media or website, which may reveal whether they sell to the general public. If they don't clarify who they serve, call and ask about their products. Explain the scope of your project before revealing you're an amateur DIY-er. This clarifies from the start that you intend to buy a few hundred dollars' worth of product, which might make the company more inclined to take your business.

Request the right type of plywood for your project

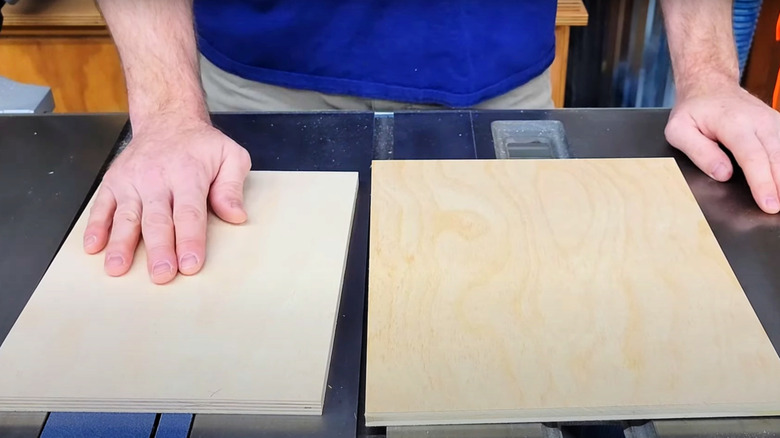

Ordering the right wood type is just as important as finding a trustworthy distributor, and you should know the secret to choosing a good piece of plywood for your cabinet project. Birchwood is a medium-density hardwood and is one of the most sought-after options for cabinetry. The composition makes it durable and damage-resistant, and birch has a naturally subtle grain pattern. It takes paint easily and is more affordable than denser cabinets, making it an easy and budget-friendly choice for DIYers. Make sure you ask for imported birch instead of Baltic birch. Imported birch is cheaper because there's a larger supply. Some woodworkers dislike this poorer quality option, but imported birch will get the job done for a much lower cost.

Instead of paying around $160 for Baltic birch, woodworker and YouTuber Wittworks advises seeking an imported version for around $40. The imported version is slightly lower quality, but it's still adequate for cabinetry, and is roughly $30 to $40 cheaper than maple hardwood boards from a big box store. Maple is typically 20% more expensive than birchwood at base price, and the quality you get at big box stores isn't always ideal, so opting for imported birch might get you comparable (or at least not highly inferior) quality. With these prices, you can save between $300 and $400 by buying 10 imported plywood boards from a distributor instead of a major retailer.

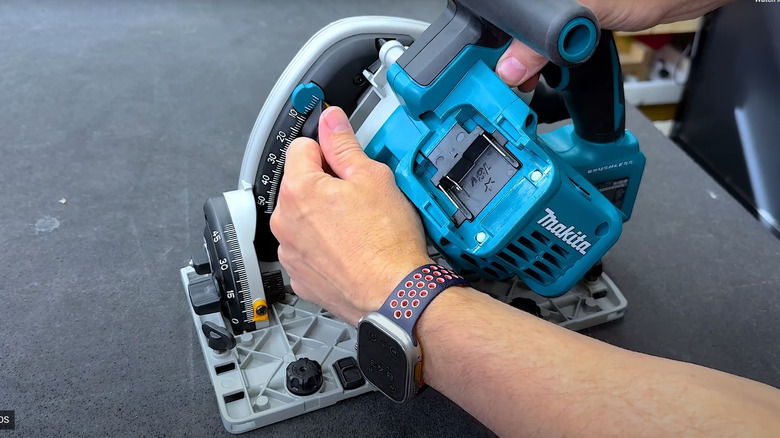

Choose the track saw that is most economical for you

There is much discourse over whether non-professional woodworkers should invest in an expensive track saw. Choosing a more economical option could be the right choice, but cheaper saws may not be as precise or as reliable, which is an important consideration if you're looking at a long-term renovation project or if you plan on doing more woodworking in the future. 731 Woodworks on YouTube tested ten track saws and rated Makita's 18-Volt Brushless Circular Saw Kit as the best for most people. Other sources corroborate this claim, calling Makita an affordable track saw option, even after pairing it with a Powertec Track Saw Guide Rail Joining Set.

The Makita saw is $599.99 on Amazon, and the guide rail is $145.99, which keeps your purchase under $1000 and can offer the greatest benefit in terms of price per use if you will use it for numerous projects. However, Wittworks states that a Wen Cordless 6.5-inch Track Saw works just as well for only $179.00 if you pair it with a better blade (such as the CMT Orange Tools Fine Finishing Saw Blades or the Freud Thin Kerf Rip Blade) for under $100. If you listen to anecdotal evidence from woodworking hobbyists and professionals, many might warn that you'll waste money making the economical choice. The Wen saw and blade are under $300, but they likely won't last as long as a reputable brand. This option is, thus, most cost-effective if you are only using the blade for a short time. With continued use, you may have to change out the saw itself sooner rather than later. There are a lot of places to cut costs while building your own cabinets, and when picking out a track saw, considering how much you intend to use the saw before making a decision is key.

Use stretchers to minimize necessary materials for a cabinet base

A stretcher is an excellent way to cut plywood costs. This involves installing a ¼-inch to ¾-inch panel instead of a full piece of plywood. It uses less material, keeps the cabinet build more lightweight, and improves side-to-side or top-to-bottom support. If you implement this method, you only use three full plywood panels per individual cabinet: two sides and one bottom piece. Instead of using two extra panels for the back and top, you replace them with four three-inch horizontal stretchers.

If you follow the previous advice about buying imported birch from a distributor, you're likely only paying around $40 to $80 per plywood sheet. Depending on how many cabinets you're making, you could save $100 or more by using stretchers instead of full panels. On a side note, don't try to cut costs when it comes to the stretcher material. Plywood is highly recommended because these pieces are responsible for supporting your build. MDF and particle board are cheaper, but they get damaged easily and don't hold up well long term. They're also difficult to drill without splitting and damaging the material, making them an impractical option for a supportive frame piece.

Try an open shelving design instead of making upper cabinets

It's common for laundry rooms and kitchens to have upper and lower cabinets. The surplus of storage space is appealing, but remember that the fewer cabinets you build, the fewer materials you'll need. Cut upper cabinets from your remodeling plans and consider replacing them with an open-shelf design instead. Open-shelf kitchens suit almost all interior designs, and they're easy to change up if you decide to upgrade to full cabinets later on. Instead of constructing full wall-mounted cabinets and hardware, it's much easier and cheaper to lay single wood planks instead.

Source the wood for open shelves from the same plywood distributor that's supplying your cabinet material. This ensures you'll get a fair price and be able to match the wood to the rest of your kitchen. If you don't want to order an extra plywood board because you don't have much space for wall shelves, you can also source super cheap BURHULT white shelves from IKEA for only $4 each. Pair them with two to three of The Home Depot's Everbuilt Gray Shelf Brackets, which are less than $2 each, and each kitchen shelf will be under $10 total. No cabinet, professional or custom-built, can compete with that kind of price.

Opt for minimalist cabinet doors instead of more complicated styles

Designing and building your own cabinet doors does give you more creative freedom, but you should exercise that right within reason. Only go for ornate cabinet door styles if you already have some modicum of skill in woodworking. Even something simple like Shaker or fluted doors takes precise table saw work, and will require extra materials. Flat panels are the way to go if you're trying to save money in every conceivable way.

The exact price difference between building flat panels versus raised or recessed panels depends on various factors, so we can't give you a precise figure. This advice is mostly based on common sense: A simpler cabinet design is easier to get right. The fewer mistakes you make, the fewer replacement materials and supplies you'll need. If you're wondering why slab cabinets are more expensive than Shaker-style when you have them done professionally, it's because they're usually made with solid wood instead of plywood. Seeing as you've already sourced your plywood, this factor isn't relevant to your DIY project and won't make a flat or slab-style cabinet more expensive. Just be aware that you will need to treat the raw plywood edges, either with something like wood filler (if you're going to paint them) or edge banding if you're staining them.

Choose cabinet doors over drawers

Often, convenient kitchens have the perfect combination of drawers and cabinets for storing kitchen utensils of all shapes and sizes. While having cabinet drawers is a perk, cutting out this design feature is a guaranteed money-saving tactic. Drawers have shorter heights and require more wood framing to build. They also use more hardware (sliding tracks instead of hinges) and require more precision to install correctly.

Again, the exact cost is too inconsistent to discern, but we can use The Home Depot's pre-assembled drawer bases as a reference. An unfinished 18-inch cabinet with drawers is $179. In comparison, an unfinished 18-inch cabinet with a door is $109. If you purchased your cabinets pre-made, choosing doors over drawers would save about $70 per cabinet installed. DIY projects only cost 25% to 50% of what retailers charge, so you can assume you're saving anywhere from $17 to $35 on materials per cabinet. If you do want to enjoy the functionality of a few drawers, consider opting for a conservative mix of deep drawers (a couple deep pot drawers will require less work and materials to construct than a bunch of standard depth drawers), and a couple shallow but lengthy drawers for utensils (which will require fewer slides and still offer a lot of functionality).

Substitute furniture for cabinets in places that make sense

If you're looking to cut back on material costs without losing valuable storage space, consider an alternative furniture solution. For instance, you can follow a TikTok DIY to build a bookshelf out of plywood and construct a shelf beside your cabinets. A backless shelf uses less wood than an enclosed cabinet, and it won't need a countertop or knobs. Use the same plywood species as your DIY cabinets to ensure a seamless paint, stain, and finish on all of the woodwork.

Instead of taking on another DIY, you can also visit Amazon, Costco, IKEA, and Wayfair for a wide selection of budget-friendly shelving units. Keep in mind that furniture colors don't look the same in person as they do on a computer screen. Your best bet is to bring scrap plywood from the cabinet project to a brick-and-mortar store. Make sure the scrap piece is painted like the cabinets so you can see how the color compares to available furniture products.

Keep in mind that wood types and colors don't have to be identical. HGTV's Jasmine Roth designed two-tone wood cabinets that added depth to the kitchen during an episode of Help! I Wrecked My House. Your main priority should be ensuring the shelving unit is cheaper than the estimated cabinet and countertop price, so you're still cutting costs as intended.

Source cabinet hardware from online retailers or visit flea markets and thrift stores

Cabinet handles, knobs, and pulls are generally inexpensive, but you can still cut costs. Follow YouTuber Fix This Build That's video tutorial for making DIY handles if you have enough scrap wood from building the cabinets. Otherwise, thrift stores and flea markets are bound to have the best deals. As someone who lives down the road from a flea market with over 700 vendors, I can tell you they're riddled with antique hardware for unbelievably low prices. There are piles of ceramic, metal, and wood knobs that many vendors will part with for a couple of dollars.

Major retailers like Amazon and The Home Depot sell knobs for less than a dollar each. These lightweight knobs are cheaper because they are made of inferior materials and often have hollow centers. It's likely other shortcuts were also taken to make them more affordable, which renders these options less reliable than a fully solid metal or ceramic knob. Decades-old hardware with a little tarnish or grimy buildup has already proven it can withstand the test of time. All you need is to use one of the best ways to clean brass hardware (or utilize the best way to clean ceramic hardware if you've picked some pretty porcelain knobs) to restore them. It's more financially responsible to buy a long-term and durable cabinet knob that won't have to be replaced for years than to pay the same price for unreliable alternatives.