The DIY Hack That Allows You To Strip Wire With Just A Screw And No Tools

We may receive a commission on purchases made from links.

Scrapping metal is a great way to recoup some of your investment on home projects, but as you start recycling more electrical wire, you eventually have to make a choice: Strip or don't strip? Even though stripped wire can yield a higher return over insulated, there are a few factors that can complicate the decision. For starters, you'll be removing the sheathing weight when stripping, which will close some of the gap between the insulated and uninsulated per-pound rates. Then, there's the labor involved. If you're only using a knife or the hidden wire stripper feature on a boxcutter, the difference in what you recoup may not be worth the time involved. To get the best value, you'll need the right tools to speed through the material.

If you choose to remove the insulation, you can always get a wire-stripping machine to blast through scrap bundles. Many drill-powered units, like the VEVOR Manual Wire Stripping Machine, come in at under $100. You could also shell out a few hundred dollars for a heavy-duty automatic stripper if you regularly recycle lots of wire. However, if you have a decent amount of wire to strip but don't feel ready for this type of investment, a cheap, handmade stripper could be the happy medium you need. There are several methods to fashion a DIY wire stripper — it's even one of the ways you can repurpose an old cheese grater. However, one of the most effective methods only requires a single screw and a piece of wood!

How to make a wire stripper with a single screw

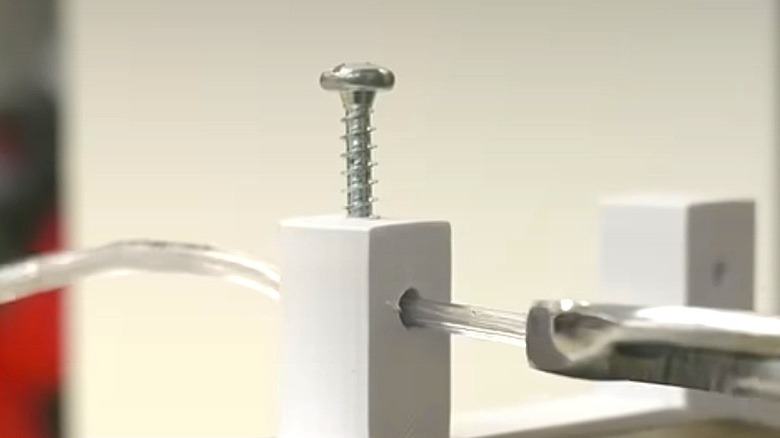

Make a simple manual wire stripper by drilling a hole in a block of wood through which you'll run the wire; drill the hole close to the edge of the block. Then, use these tips for drilling the perfect pilot hole to drill down through the board's edge directly above the other hole. Bore until the bit reaches the other hole (the two holes will be perpendicular to each other). Use a file to sharpen the head of a pointed-tip screw, such as a drywall screw. Screw it into the pilot hole until the sharpened point peeks into the hole where you'll run the wire. Clamp the board to a sturdy surface, and run your wire through the hole. Use pliers to firmly grip the wire and prevent injuries while you pull. As the wire passes through, the sharp screw will tear the sheathing, making the underlying metal easy to remove. Move the screw in or out of the hole to adjust as needed for a clean rip.

For more function, do as the creators at the YouTube channel Hammer II Hammer did by adding holes of varying diameters. With this, you can easily strip wires of different gauges without making adjustments. Offering a unique twist, @CopperKing made a wire guide with two extra screws, avoiding the trouble of lining up drilled holes. Whichever way you make your new tool, it only takes a few cents worth of supplies and a couple seconds of work to make wire stripping a far easier process.