Why You Should Never Use Wood Glue In The Cold

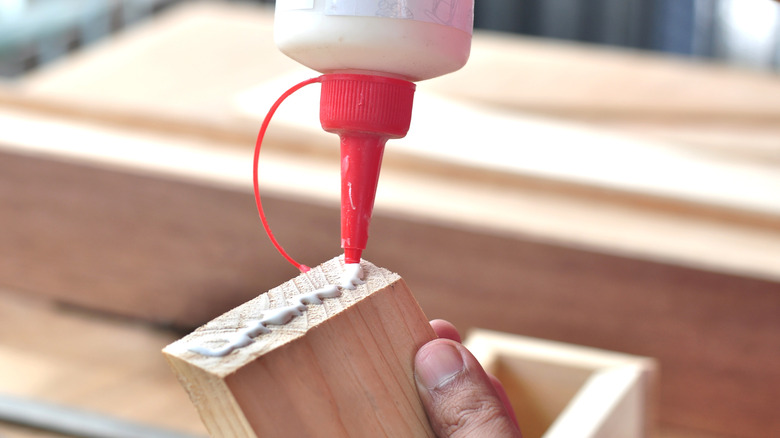

Picture this: you're ready to start your woodworking masterpiece. You grab your wood glue, slather it, and press the pieces together, expecting perfection. But wait! The air is chilly, your workshop feels like a freezer, and you wonder if the glue is working. Spoiler alert: it probably isn't. Using wood glue in the cold can lead to disappointing results. For starters, cold temperatures make wood leave behind a chalky residue that doesn't just look bad — it weakens the bond. Worse still, the glue loses its adhesive strength because it can't cure appropriately in low temperatures.

When wood glue is exposed to cold temperatures, it struggles to dry and cure the way it is supposed to. Instead of forming a smooth, invisible bond, it can leave behind an unsightly chalky residue. The residue doesn't just look bad; it's nearly impossible to sand away without damaging your project. So, unless you're going for a rustic disaster, avoiding wood glue in the cold is best.

Another reason wood glue fails in the cold is because its adhesive properties take a serious hit when temperatures drop. Wood glue relies on a chemical reaction to create a strong bond, and cold weather slows this reaction down — or stops it entirely. Instead of forming a tough connection between wood pieces, the glue stays runny or brittle, like a popsicle on the verge of melting. This means your carefully glued pieces can easily come apart with the slightest pressure. And even if the glue eventually dries, it won't have the same strength as it would in warmer conditions.

Wood glue alternatives for your cold weather projects

When wood glue fails, epoxy resin swoops in to save the day. Unlike wood glue, epoxy doesn't mind the cold. It thrives in temperatures as low as 35 degrees Fahrenheit. Epoxy resin consists of two components –- resin and hardener – that you mix to create a super strong bond. Epoxy resin works well on wood, metal, and even plastic, making it a versatile choice for various projects. Plus, it's water resistant and can handle various temperatures without losing its strength. The only downside? It takes a bit more time and effort to mix and apply.

Construction adhesive is another excellent option for larger woodworking projects or outdoor tasks. This heavy-duty adhesive is designed to work in cold conditions, including cold weather. It bonds quickly and can hold heavy materials in place, making it ideal for projects that require extra strength. Unlike wood glue, construction adhesive doesn't rely on a chemical reaction that low temperatures can disrupt. Instead, it is formulated to perform consistently, even when the weather isn't cooperating. Keep a tube handy for those cold days when wood glue just won't cut it.

Polyurethane glue is a flexible adhesive that's perfect for cold-weather woodworking. It expands as it cures, which helps it fill in gaps and create a strong bond even in less-than-ideal conditions. Polyurethane glue is also waterproof, so it's great for projects that need to withstand moisture or temperature changes. However, it's important to note that this glue can get a bit messy, as the expanding foam can ooze out during curing.

Best practices for achieving strong bonds year-round

To ensure your adhesive bonds well, you need to follow some tips. First, prepare your surface. Before applying any adhesive, ensure your surfaces are clean, dry, and smooth. Dust, grease, and moisture can interfere with the adhesive's ability to bond properly, leading to weak or uneven results. Use sandpaper to smooth out rough edges and wipe down the surfaces with a clean, dry cloth to remove debris. This extra step might feel like a chore, but it's the price to pay for a small, reliable bond. Proper preparation is half the battle.

Next, choose the right adhesive from the various types of adhesive you should have on hand. Wood glue works perfectly for warm-weather projects, but for cold-weather or outdoor tasks, opt for alternatives like epoxy resin, construction adhesive, or polyurethane glue. Read the labels carefully to ensure the adhesive you're using is designed for your working conditions. A little research goes a long way to preventing glue failures and ensuring your hard work isn't wasted.

Lastly, allow adequate curing time. Patience is a virtue, especially when it comes to adhesives. No matter how great your adhesive is, it won't work correctly if you don't provide the appropriate time to cure. This is especially true in cold or humid conditions, where curing times can be longer than usual. Follow the manufacturer's instructions for curing time and resist the urge to rush the process.