Ditch Foam Core Insulation And Try One Of These Eco-Friendly Alternatives Instead

Although foam core insulation was a popular choice in the past, foam core made of extruded polystyrene insulation (XPS) is being traded out for more eco-friendly options. Over the decades, new types of insulation have hit the market. Many of these brands and materials have several pros over traditional foam core.

Below are nine eco-friendly alternatives to foam core. These insulation types are produced by more sustainable methods, many work longer and more effectively, and have fewer ecological drawbacks. Each of these materials and methods is deemed eco-friendly based on several factors, including their material quality, R-value, and longevity. Longevity is important, as longer-lasting insulation doesn't need replacement as often, decreasing production demands and product waste. The material quality refers to whether insulation is made of recyclable or renewable materials, and the R-value is a calculation of how well the insulation actually works — a higher value indicates it provides better insulation.

The insulation types discussed below have hit the market in the past two decades. Each one is more sustainable than traditional foam boards made of XPS. If you're looking for green project upgrades you can do to keep your home sustainable, installing one of these insulation types is definitely worth considering. Read on to learn more about the pros of using these environmentally friendly insulation materials, as well as the estimated cost of putting them in your home.

Aerogel is formulated with synthetic and bio-based materials and has air for filler

Aerogel insulation is a unique silica-based formula and incorporates various other types of materials. The production process uses carbon, copper, gold, iron oxide, or other organic synthetic blends. The structure of the material is porous and not very conductive, making it a great filler for insulating walls, vehicles, and other constructions. It fits in narrow areas and is hydrophobic, making it resilient against moisture damage. Once installed, it can last up to 50 years, though this number may be lower in the presence of high temperatures and excessive humidity, according to a 2018 study published in the Microporous and Mesoporous Materials scientific journal.

Aerogel is lightweight at only a third of the size of other insulation types while having a remarkable R-value of 10.3 per inch. The downside of the thin composition is that it doesn't work with some construction materials and is fragile. Currently, this is not a popular insulation choice because it is expensive to produce and purchase as insulation. Product availability is limited, and it's trickier to acquire than more common options. However, while prices are high now, research indicates costs could go down if the production process is fine-tuned, so this is definitely a product worth keeping an eye on — especially if you're only planning on replacing your insulation in a few years' time.

Cellulose insulation is made from recycled paper and textile products

Cellulose insulation became widespread in the 1950s, and over the decades, there have been changes to how it's sourced and made. Modern cellulose is mostly made of recycled paper — typically newspaper — and treated with non-hazardous chemicals. It's also made with textile scraps, like cotton and denim. The blended material contains more recycled material than most forms of insulation, and its popularity makes it easy to find and cheap to install. Prices can vary depending on the type and where it's applied, but generally, it ranges between $2 to $4 per square foot. Along with containing high amounts of recycled materials, cellulose insulation may help keep carpenter ants out of your walls, because it is commonly treated with boric acid, which is both a fire retardant and a compound used for controlling carpenter ants and other pests.

Despite being sustainably made and budget-friendly, there are a few downsides. Earlier forms, such as those produced in the 1970s, were oftentimes not installed thoroughly, making them inefficient insulators. Modern cellulose has a decent R-value at around 3.2 to 3.8 per inch. The main concern with this material is that it can't be exposed to water since it's highly absorbent. If it become saturated, this can decrease insulative effectiveness and trigger risks of mold and mildew growth.

Thermacork insulation is produced using highly sustainable methods

Thermacork is a brand that has made cork into one of the greenest and most effective insulation methods; the R-value is around 3.6 to 4.2 per inch. This company processes oak tree cork into blocks, using cork dust from the sorting process as fuel to power the machines, supplying up to 93% of the energy needed to make the cork boards. The process of stripping cork also doesn't harm trees and the cork-yielding bark grows back over the course of 9 years. The finished product is 100% recyclable and ranks as one of the Top 10 Green Building Materials, as rated by Building Green, a consultant company that advocates for eco-friendly practices. All of this combined makes cork a great insulation material, as well as one of the best non-toxic flooring options you can feel good about installing. Contrary to popular belief, cork flooring can last for a long time before it needs to be replaced, and the same appears to be true for cork-based insulation, as ThermaCork states that their product can retain its insulation properties for decades.

The primary concern about Thermacork is that the transportation footprint is high. Over half of the cork is imported from Portugal, making the importation process the most environmentally-taxing part of cork insulation production. It's found at online retailers outside of the U.S. for around $3 to $6, not including shipping. Thermacork is harder to find than options like cellulose and wool, but we did track down one supplier that services the western U.S. and stocks Thermacork Insulation.

Sheep wool insulation is made from sheared wool fibers without harming animals or the environment

Sheep wool, especially from brands like Black Mountain USA and Havelock Wool, is an excellent insulation choice for the environmentally conscious. These brands use 98% to 100% sheep wool in their product, making it almost entirely from a completely renewable resource. These brands are highly durable, long-lasting, have no known negative environmental side effects, and are naturally mold and mildew-resistant. Black Mountain USA wool has a 3.7 R-value per inch, while Havelock Wool has a rating of 4.

Sheep wool insulation products are neither particularly cheap or expensive, as they cost around $2.10 to $4 per square foot. The main concern is that sheep wool insulation typically doesn't have a vapor barrier, and you may have to pay for additional installation which can up the total cost by $0.30 to $0.50 per square foot. Vapor barrier installations are commonly needed for insulating floors, walls, and ceilings. Although Havelock Wool has great environmental ratings, it has a similar downside to Thermacork — the wool is imported from New Zealand and costs money and resources to transport. Wool insulation is available from a few different retailers, but Eco Building Products stocks both Havelock Wool and Black Mountain USA insulation.

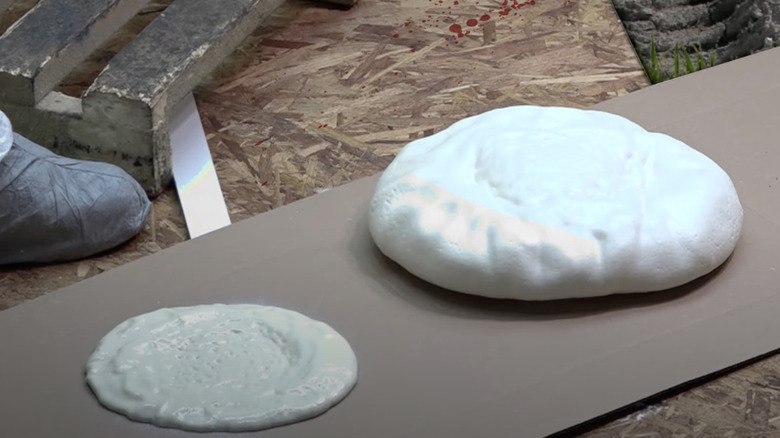

Icynene insulation is based on castor oil and doesn't contain trapped gases

Icynene is a brand that creates foam insulation made of castor oil and air. The foam composition has open cells that don't trap dangerous gases commonly found in polyurethane foams, such as formaldehyde. The spray foam version is made completely from natural and recycled materials. Even with its eco-friendly composition, it has a medium to high R-value range of around 3.6 to 4 per inch.

The main downside to Icyene is that it's a relatively new product which is still under study. Only factory-trained and authorized installers are able to spray on the insulation. You cannot DIY this product, which automatically means the cost will be a little higher than DIY-able options. The estimated cost varies and there isn't any official range to go by at this time. Various online blogs and websites speculate on the prices; the general agreement is that it's costly compared to other insulation types. On another note, professionals are responsible for installing this product because the foam releases chemicals during the process. Rooms must be ventilated afterward, which raises questions about how it affects indoor air quality over time. That said, this is another product that is worth keeping an eye on. Despite its drawbacks, Icyene is one of the few eco-friendly insulation solutions that can be sprayed, making it a potentially valuable addition to the market.

Expanded polystyrene insulation is plastic, but saves remarkable amounts of energy and is recyclable

There is one type of foam board insulation that has green potential. Expanded polystyrene insulation (EPS) is made from plastic, but is incredibly effective at saving energy, making it a potential choice for insulation in home walls. The R-value goes as high as 4.2 per inch. The high R-value reduces how much energy a home uses over time, which makes EPS a green option in some regards, despite the plastic. It's lightweight and can be recycled into new plastic products, giving it sustainability potential. This product is easy to find due to its affordability and availability, and is sold for less than $1 per square foot at popular home improvement stores like The Home Depot and Lowe's.

The main problem with this material is that it isn't always recycled correctly at the end of its life cycle. The material usually lasts around 50 years, but it's not biodegradable if it ends up in a landfill. It takes so long to degrade that there is no definitive answer on the timeframe. Therefore, whether this product is "green" is ultimately up to the contractors', installers', and homeowners' decisions. Given that it's plastic, one of the potential concerns you may have around EPS is potential off-gassing of VOCs. Currently, the general consensus is the EPS does not emit harmful amounts of VOCs (although the manufacturing of polystyrene is a different story). If you are concerned, consider installing EPS in an area of your home where you don't spend significant amounts of time, such as your garage (and if you're still not sure if it's the ideal pick, here's how to choose the right type of insulation for your garage).

Fiberglass insulation is long-lasting and contains recycled glass

Fiberglass insulation was invented in the 1930s, but has changed significantly since then. In just the past few decades, improved technology and production changes have made this insulation type far more eco-friendly. Many manufacturers use recycled glass, have stopped using the chemical formaldehyde, and leverage energy-efficient production methods to lower carbon emissions. Not all companies use recycled glass, but it's easy to find out by ensuring they're certified by UL Environment or a similar organization. It's a budget-friendly option for eco-conscious households and usually costs around $0.30 to $1.50 per square foot. The affordable price range is one of the reasons why you might want to consider insulating an attic with fiberglass.

Although the fiberglass industry has made many changes to be more sustainable, the product is not 100% made of recyclable material. The R-value can be as low as 2.2, which is a significantly lower range than other insulation types. Another con is that the material appears to hold up for a lifetime, but its actual effectiveness does not last that long. Rather it only lasts for around 15 to 20 years before the insulative properties diminish.

Hemp wool insulation uses biodegradable ingredients and is sustainably made

Hemp wool material is listed under USDA's BioPreferred Program, making it an obvious eco-friendly choice for insulation. During production, it absorbs carbon, making it carbon-negative. When it is time to replace this insulation with a newer version, the old material is both biodegradable and compostable, making it eco-friendly at all parts of the lifecycle. If you're looking for a more direct example, Hempitecture is a popular brand that produces hemp wool insulation. Their material has a 3.69 R-value per inch and is made of 90% natural fiber.

The only primary problem with hemp wool is unrelated to the environment. The United States has placed restrictions on hemp due to its botanical relationship to THC-containing cannabis. Production is severely limited, and many big-name stores don't carry hemp wool. There are online retailers that stock hemp wool insulation products, but the prices are slightly higher than other options, averaging around $1.80 to $2.40 per square foot.

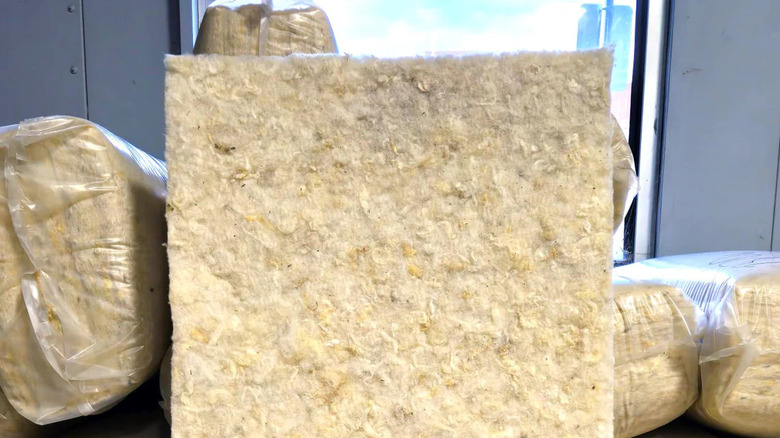

Mineral wool insulation lasts a lifetime and is recyclable

Mineral wool is also referred to as glass, slag, or stone wool, and contains up to 40% of recycled content from metal factories. Rockwool is a popular producer of this kind of wool, and their products don't release any known short-term or long-term toxic byproducts. The production process has a minimal environmental impact; there are no harmful emissions and there's no direct impact on the Earth's ozone. The R-value is about 4.2 per inch, which also means it's effective at saving energy.

Given its eco-friendly process, high energy ratings, and availability, mineral wool is an overall top pick. You can find mineral wool products at local hardware stores and nationwide chains like Home Depot and Lowe's, but inventory and options may be limited depending on your area. It falls in a lower price range than natural sheep or hemp wool at about $1.40 to $2.50 per square foot, (but does cost more than some of other options on this list). One drawback is that it's a fairly dense material, making it harder to install or remove on your own.