Everything You Need To Know About Sharpening A Specialty Drill Bit

We may receive a commission on purchases made from links.

Most DIY-ers use traditional drill bits to create holes in wood and other items. Sharpening a regular drill bit can be done by hand or with a bench grinder. But what if you use a step bit, also called a unibit? Are there ways to sharpen this specialty cutting tool? You can, but as you probably guessed, it takes some particular tools and techniques. You can use power tools like a Dremel or an angle grinder with a metal sharpener attached, or you can hone it by hand with a whetstone.

A unibit is a pyramid-shaped bit that has different diameters. It looks like stair steps or discs stacked on top of each other. The unibit has a greater diameter at the bottom and becomes narrower until forming a point at the tip. You can make different sizes of holes with the cutting tool without having to change it out by simply adjusting the depth at which you drill. A traditional step bit design has a V-shaped notch that creates a cutting edge as it spins. You'll sharpen it along the rim of this notch.

A step bit can be quite expensive, typically carrying a price between $25 and $75 at The Home Depot. For this reason, sharpening it can be a better option for your budget than discarding an old one when it becomes dull and purchasing a new piece. Here's more about the techniques needed to sharpen a specialty step bit.

Sharpening your specialty drill bit

To sharpen the step bit, you can use a cone-shaped grinding bit with a Dremel. You should work on the smaller of the two faces inside the notch of the step bit. Make sure the grinder on the Dremel is spinning outward,away from the edge of the bit. If you're holding the unibit by the handle and pointing in upward in front of you, the grinder should be spinning clockwise. Work it up and down the left rim of the interior notch, which sharpens the cutting edge. Keep working until you can match the factory angle.

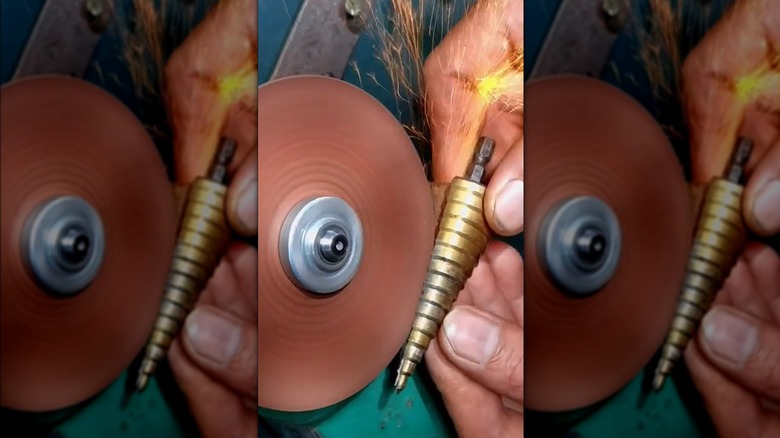

Another option is to use a sharpening disc made for metal attached to an angle grinder. Secure the machine to a workbench with a bracket, turn it on, and carefully move the unibit's cutting edge — on the interior of the notch — across the spinning face of the grinding disc. This will sharpen it quickly.

If you prefer to sharpen it manually, use a diamond sharpening stone. Place the smaller of the two faces of the unibit flat against the edge of the stone and slide it back and forth to hone it. Diamond sharpening stones can cause significant scratches in the metal, so use them carefully on the unibit.

Watch out for common mistakes

When grinding the bit, never apply the grinder to the round section of the notch. The flat edge is what does the cutting, and it needs to maintain its consistent rim. Always sharpen it from the inside of the notch to remove burrs. Never start on the curved portion or the exterior side of the notch or you'll damage the cutting edge and create uneven holes when you drill with it later.

If you decide to use an angle grinder, exercise a lot of caution. If you slip while using this sharpening tool, you could take a chunk out of the step bit and ruin it. You also could cut yourself, as the angle grinder spins very quickly. Always wear safety goggles or flying metal particles could end up in your eyes. The angle grinder will also create a lot of sparks as you're sharpening the unibit, which may make you uncomfortable using this method.

If you are sharpening the step bit manually, avoid using an aluminum oxide stone or you will damage the stone's edges. Also keep in mind that the process will take far longer than using a grinder or Dremel. Household Hacks says it could take as long as 10 minutes to manually sharpen a really dull bit. However, doing the process manually reduces the chances of injuring yourself or taking a large chunk out of the metal tool.