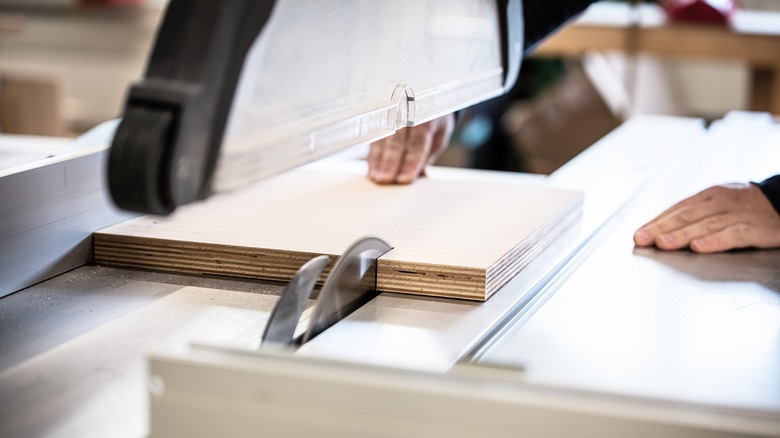

How To Easily Sharpen Your Dull Table Saw Blades

We may receive a commission on purchases made from links.

Shop jigs are one of the joys of woodworking. Not many hobbies include comparable projects that can make the hobby better while using the hobby itself. Imagine frying up a better skillet or growing a nice little cultivator in your garden. And so, when it comes time to sharpen or replace a table saw blade, woodworkers and tradespeople often turn to shop-made jigs... homemade tools that are used to improve a workshop's other tools. While hand saws are usually sharpened manually with a file, table and other circular saw blades can often be sharpened quickly using power tools... even the table saw itself.

Most jigs provide functionality that the original tool doesn't have (like a table saw finger-jointing jig) or perform very poorly (like a crosscut sled). But circular blade sharpening jigs are meant to restore the original capabilities of your saw blade because the tool is better, easier to use, and safer with a sharp blade. Signs of a dull blade include chipping, splintering, or tear-out; burn marks on wood; putting more effort into cuts; and cuts that take more time. Dull blades can also increase the risk of kickback, overheat the blade so that it loses its temper, and shorten motor or bearing life. In fact, working with sharp tools is on our list of safety precautions you should be taking for your next home project. Cleaning a blade properly can improve its cut temporarily, but you'll eventually need to sharpen or replace the blade.

Sharpening your table saw blade with your table saw

One nifty blade-sharpening jig comes via YouTube boat-builder and RC plan aficionado @jamesboatbuild. His jig for sharpening table saw blades holds the blade at a 45-degree angle to the tabletop and perpendicular to a diamond blade that does the sharpening. (A diamond-impregnated blade is required for sharpening blades with carbide tips on its teeth, and they also make it easy to sharpen other household tools, like lawn mower blades.) The blade attaches to a bolt in a C-shaped groove that swings up and away from the diamond blade in either direction. Adjusting the bolt's position gives you the ability to fine-control the angle at which the blade meets the diamond wheel so that you can match the original angle of the blade's teeth. A large wooden washer and nut hold the blade in position.

Another simpler approach uses a piece of wood cut at a 20-degree angle with a diamond file taped to it and doesn't even require removing the saw blade from the saw. Simply lay the jig flat on the saw's tabletop, turn the blade so that a tooth rests against the diamond hone, and move the jig back and forth to sharpen the tooth. Then move on to the next tooth. The 20 degrees is a solid rule of thumb, but you might need a slightly different angle for any particular blade based on its tooth count, the original tooth angle, etc.

Other ways to sharpen your dull table saw blades

Of course, @jamesboatbuild's jig isn't the only table saw sharpening jig in town. Other DIY jigs work without the table saw by incorporating a diamond grinding wheel on an angle grinder or using a jig with a manual file instead of a spinning diamond blade. It seems like a bit of false economy, given that the labor you save putting on and taking off the diamond blade is far outstripped by the labor of sharpening with a file. If you don't happen to have a table saw but do have a circular saw blade that needs sharpening, either approach might be best for you. There are also commercially available products for sharpening circular saw blades, which you would likely have to order online. Harbor Freight used to sell an electric sharpener but now appears to only sell replacement grinding wheels for it. Amazon sells a number of electric sharpeners between $130 and $240.

One element missing from most homemade jigs and store-bought sharpeners is a means of indexing the blade's teeth... that is, stopping the rotation of the blade and the right point for sharpening the next tooth. The mechanism can be simple... a stop that simply slides or flips into place against one of the blade's other teeth. However, it must be adjustable because saws with different tooth counts will need indexing at different points in the blade's rotation. Now the only question is: How do you make the sharpening jig if your blade is dull?